MASTER’S FIELD PROJECT

APRIL 2019

When reflecting on the work of our practice, the chamfered corner, is a recurring interest. This detail has developed over the years from our preoccupations with the Miesian re-entrant corner, the simplicity of a trabeated structure, and a desire to find ways of expressing a deep façade.

Simple chamfers in concrete and stone were employed in recent completed projects for Hampshire House and The Sultan Nazrin Shah Centre, Oxford. At the Master’s Field site in Oxford, currently under construction for Balliol College, a corbelled chamfered detail is incorporated in a load bearing façade. This project comprises eight student accommodation buildings and a pavilion arranged around a series of courtyards overlooking a cricket pitch.

A brick-clad chamfer at the corner between two windows is used throughout the accommodation buildings. This establishes a shifting perspectival relationship as one moves through the site, and gives all the buildings a common language. Corbelled brick and concrete lintels and mullions set up a trabeated structural rhythm which clearly defines each individual student bedroom and creates a delicate play of light and shadow across the façade. A series of finely detailed brick and concrete panels are layered within the depth of the window reveal, articulating a secondary rhythm which expresses the transition from solid to glazed elements.

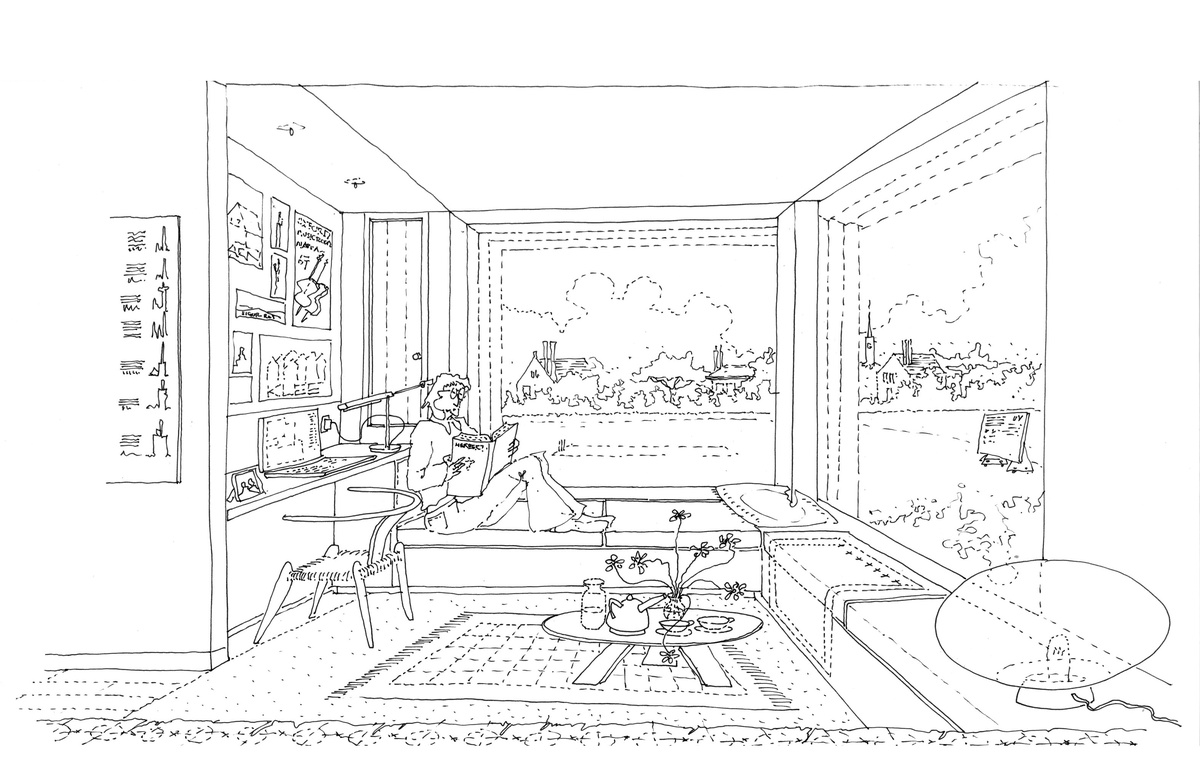

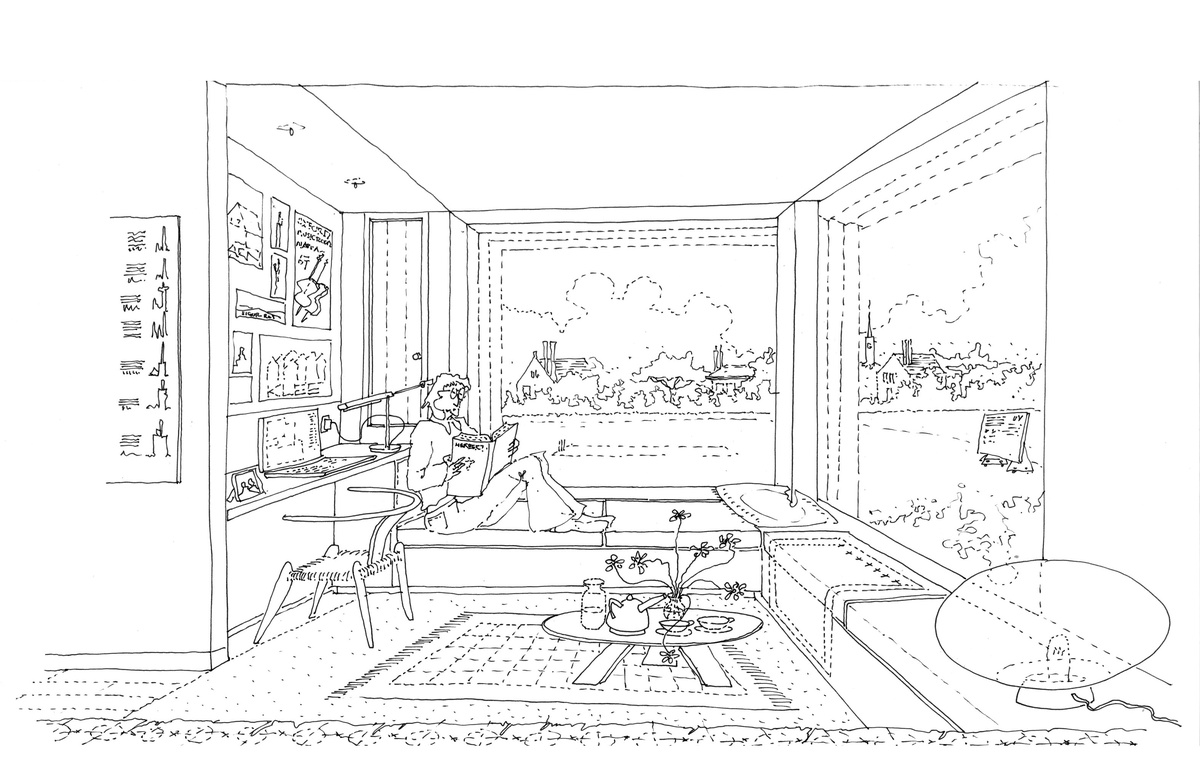

The detail enables the depth and structure of the wall to be elegantly expressed, maximizing its presence when viewed externally and minimizing its presence internally. It also forms a generous threshold which provides privacy for students inside engrossed in their study. For moments of welcome distraction, the large picture windows frame uninterrupted views over the cricket pitch and across the campus.

The expression of a chamfered corner produces challenges in construction, particularly when expressed in precast concrete components clad in corbelled brickwork. When forming acute angles with orthogonal bricks, special consideration must be given to alignments and bonding. Interface details demand careful thought regarding sequencing and tolerances to achieve a symbiosis of structural performance with aesthetic ambition.

Externally, in the plan detail shown here, the apex of the chamfer is formed from stacked brick headers. This exposes three faces of each brick, limiting the choice of bricks, which are typically produced with only one finished stretcher face. Brick specials are required to form the chamfered corbel of the lintels, and grids are carefully set out to ensure alignment of vertical and horizontal corbelling. We looked to the meticulously detailed and crafted brickwork of Jensen-Klint’s masterpiece, Grundvig’s Church in Copenhagen, for expression of stepped vertical forms.

Internally, minimising the corner where the windows meet produces intricate challenges in the alignment of linings, blinds, reveals and fitted furniture. This complex resolution of constituent parts all work hard to achieve the aesthetic objective of the simple glazed chamfered corner.

Detail Key

1.Whitewashed ply bench 2. Aluminium window 3.Whitewashed plywood reveal 4.Plasterboard 5.Rigid insulation 6.Steel window fixing brackets 7.Metal pressing 8.Wind post 9.EPDM/ vapour barrier 10.Mineral wool insulation 11.Breather membrane 12.Steel restraint brackets 13.Corbelled brick faced precast concrete mullion 14.Flashing 15.Concrete cill 16.Concealed curtain track 17.Oak joist over 18.Concealed roller blind 19.Timber panels 20.Timber framed window 21.Prelaminated timber frame 22.Precast concrete mullion 23.Precast concrete coping over

A STONE GLOSSARY

MAY 2018

William ‘Strata’ Smith’s 1815 Geological Map, the first nationwide geological map ever published.

We are in the process of choosing the stone to be used for a new building in Cambridge. It has been an apparently exhaustive journey through marbles and limestones from the UK, Europe and beyond. We amass endless samples, and talk in detail to quarrymen, masons and engineers about bed heights, weathering, and reliability of supply, as well as the inevitable costs to quarry the stone, cut it to shape, and fix it together to form a building. One of the most fascinating elements of this process are the specialist terms used to describe building stones and their properties. Below is a list of a few favourite words, ordered to explain the material properties that have so far governed our explorations for this new project.

The Clipsham Quarry at Rutland in Lincolnshire. Clipsham Stone occurs in the Inferior Oolite of the Jurassic System, where it was laid down between 174 and 163 million years ago. Clipsham is a popular building limestone with a characteristic golden colour. We have recently worked with it at Bishop Edward King Chapel in Cuddesdon and the Sultan Nazrin Shah Centre in Oxford.

Bedding plane

Many building stones, including all limestones, are sedimentary rocks, formed by the gradual settlement and compression of underwater sediment over millions of years. The directional way in which they were formed governs their properties and how they can be used as building stones. Most UK limestones must be used ‘naturally bedded’, i.e. orientated in the building in the same way that they were formed in the ground. This means the height of the blocks is limited to the depth of the bed, rarely more than 1m in the UK. ‘Face-bedding’, when blocks are laid so their bedding planes are parallel with the vertical face of the block, can lead to rapid weathering and crumbling.

Metamorphic

A stone that began as another type of rock and changed as a result of exposure to heat and pressure over geological time. Marble was originally limestone, and is chemically identical to it. However, the metamorphic processes changed its physical properties so that it does not have bedding planes, and can be cut and orientated in any direction. This makes it ideal if tall blocks are required.

Precipitation

The chemical process by which Travertine is formed, usually when geothermally heated water is exposed to the air, causing it to degas and carbonate minerals to precipitate out from the water. Although a type of limestone, its distinctive formation means it also doesn’t have bedding planes and is workable in much longer, thinner pieces than sedimentary stones.

Oolitic

A type of limestone made from an amalgamation of individual grains called ooliths. An oolith is a tiny carbonate particle surrounded by concentric layers of calcium carbonate, which were deposited as the ooliths were rolled around on the bed of the clear shallow sea in which the stone was formed. This gives the stone an even structure so it can be cut or sculpted in any direction, a characteristic which makes oolitic stones ‘freestones’. Portland Stone is an oolitic limestone used extensively in London’s historic buildings, perhaps most famously in churches by Cristopher Wren and Nicholas Hawksmoor, including St Paul’s Cathedral and Christ Church Spitalfields.